Your Process

LEAVE NOTHING BEHIND.

Solutions for the plastic industry.

POWER YOUR PROCESS. PERFECT YOUR FLOW.

All our air conveying solutions for the plastic industry are designed to keep your production flowing. Whether you’re handling trim, waste, granules or regrind, our systems are precision-engineered to improve efficiency, protect product quality and maximize uptime.

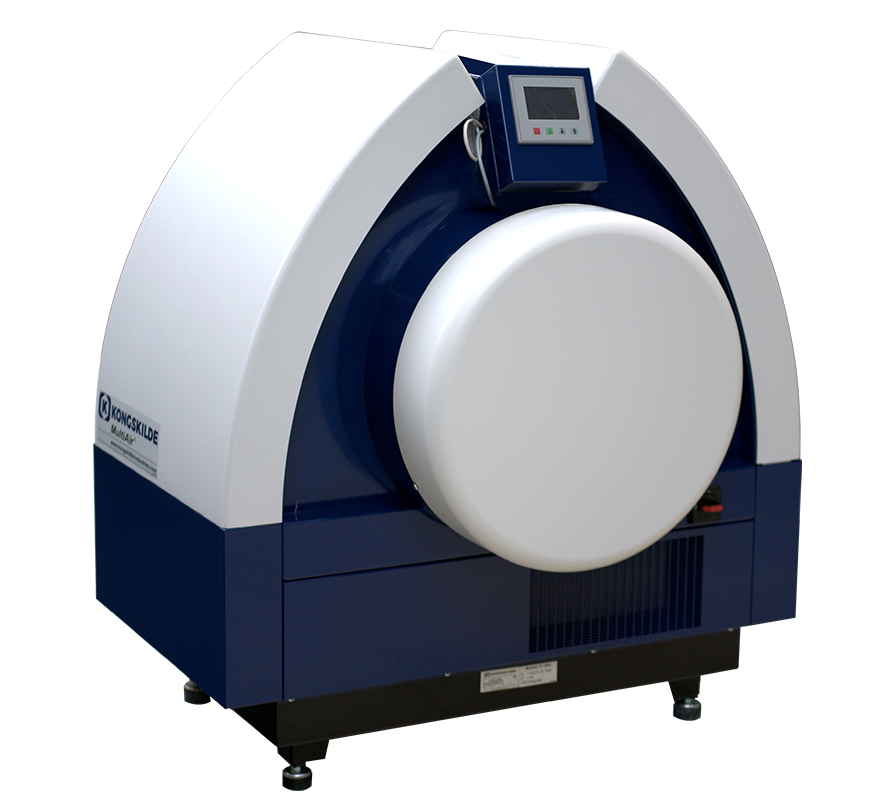

Blow moulding

Improve your ROI in blow molding by reducing material costs and minimizing downtime. Our de-dusting and separation systems remove dust, fluff, and debris from regrind based on material density. Resulting in cleaner regrind, higher-quality parts, and fewer clogged vacuum loaders. The benefits? Less scrap, more uptime, and a cleaner production environment.

EPS packaging

EPS and EPP conveying demands a careful balance between airflow and material integrity. Our Venturi-based systems gently transfer low-density granules while preserving their shape, reducing fluff, and lowering material waste. The result is cleaner regrind, higher-quality output, and a faster ROI. Using standard components, our systems can be installed anywhere and are suitable for both high- and low-capacity lines.

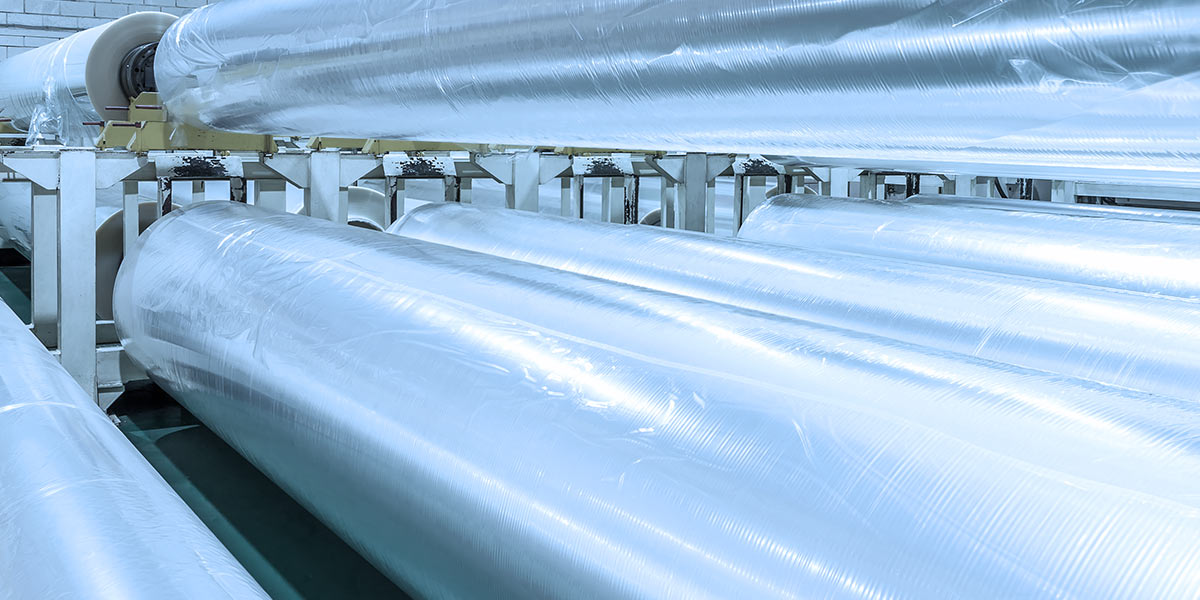

Film Production & Plastic Roll Converting

Improve the efficiency of your plastic film production by quickly removing the continuous trim produced by the re-winding process. Our pneumatic systems quickly remove trim through closed pipe systems. Trim can be directed to dedicated destinations for reuse or disposal, with different materials kept separate to support efficient handling and material recovery.

Flexible Packaging

Flexible packaging waste needs to move fast. Our pneumatic systems quickly and cleanly transport trims, off-cuts, punch-outs, and rejects directly from the production area through enclosed pipe systems. If needed, the waste can be sent outside the production area. This helps free up floor space, reduce manual handling, and maintain a cleaner, safer working environment.

Injection Molding

Move polymer efficiently around your injection molding facility with a pneumatic conveying solution tailored to your process. Convey sprues to reclamation or gently transfer finished parts to packing or storage. Reduce manual handling and energy use with a clean, reliable system built for uptime and precision.

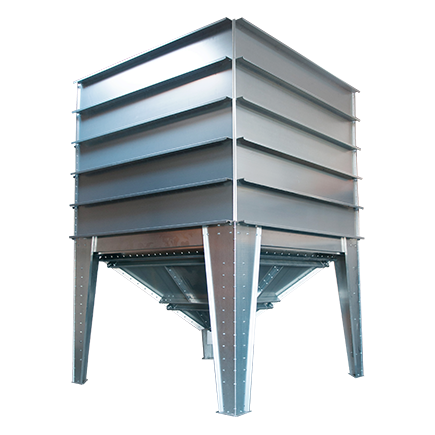

Rail car

Convey material from rail car to storage quickly, safely, and without contamination. Our pneumatic system offers a flexible setup. It significantly reduces the risk of granulate melting during transport compared to typical PD pump systems while protecting product quality and improving efficiency.

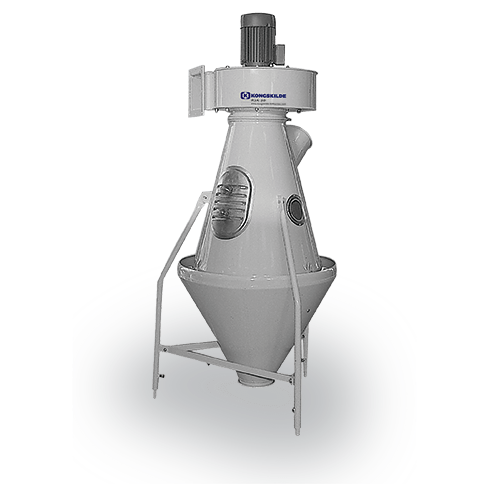

Recycling

Streamline recycling and improve your work environment with efficient pneumatic conveying. Move granules, flakes, and ground material directly from grinders or silos. Convey pellets, plastic bags, or bottles with ease, and enhance material quality by separating light and dense fractions during handling.

Thermoforming production

Ensure a steady supply of material to your screw extruders and keep your thermoforming process running without interruption. Our pneumatic systems quickly convey plastic flakes from the grinder to big-bag stations, recycling areas, or waste depots. This reduces manual handling, frees up space around the line, and an aspirator system improves the reuse value of flakes through efficient de-dusting.

- Conveying granules from various points to different destinations

- Conveying granules from various points to different destinations

- Conveying granules from various points to a single destination

- Cut trim removal

- Conveying of granules in low-capacity installations

- Conveying of granules in high-capacity installations

Applications for better flow

Every process has its pressure points. Whether you’re moving granules, capturing trim, reusing regrind or want to dedust, we can help. Let’s improve flow with high-performance pneumatic systems designed to add value, reduce waste and protect product quality.

The right product for every process.

We’re more than engineers. We’re problem solvers.

Our job doesn’t stop at installation. Whether you need technical support, ongoing maintenance or fast spare parts delivery, we’re here to keep your systems performing at their best.

- End-to-end service. From installation and commissioning to global on-site support.

- Smart maintenance. Including preventive service, performance monitoring and flexible service packages.

- Easy access. Spare parts, manuals, videos and technical documents when and where you need them.

With a 75-year legacy of helping companies like yours, we have truly seen it all. We’re creative thinkers, seasoned engineers, and industrial conveyance experts, but most of all, we’re really great problem solvers. Don’t hesitate to ask how we can help.