Case Study

Plastic

Recycling

Regrind

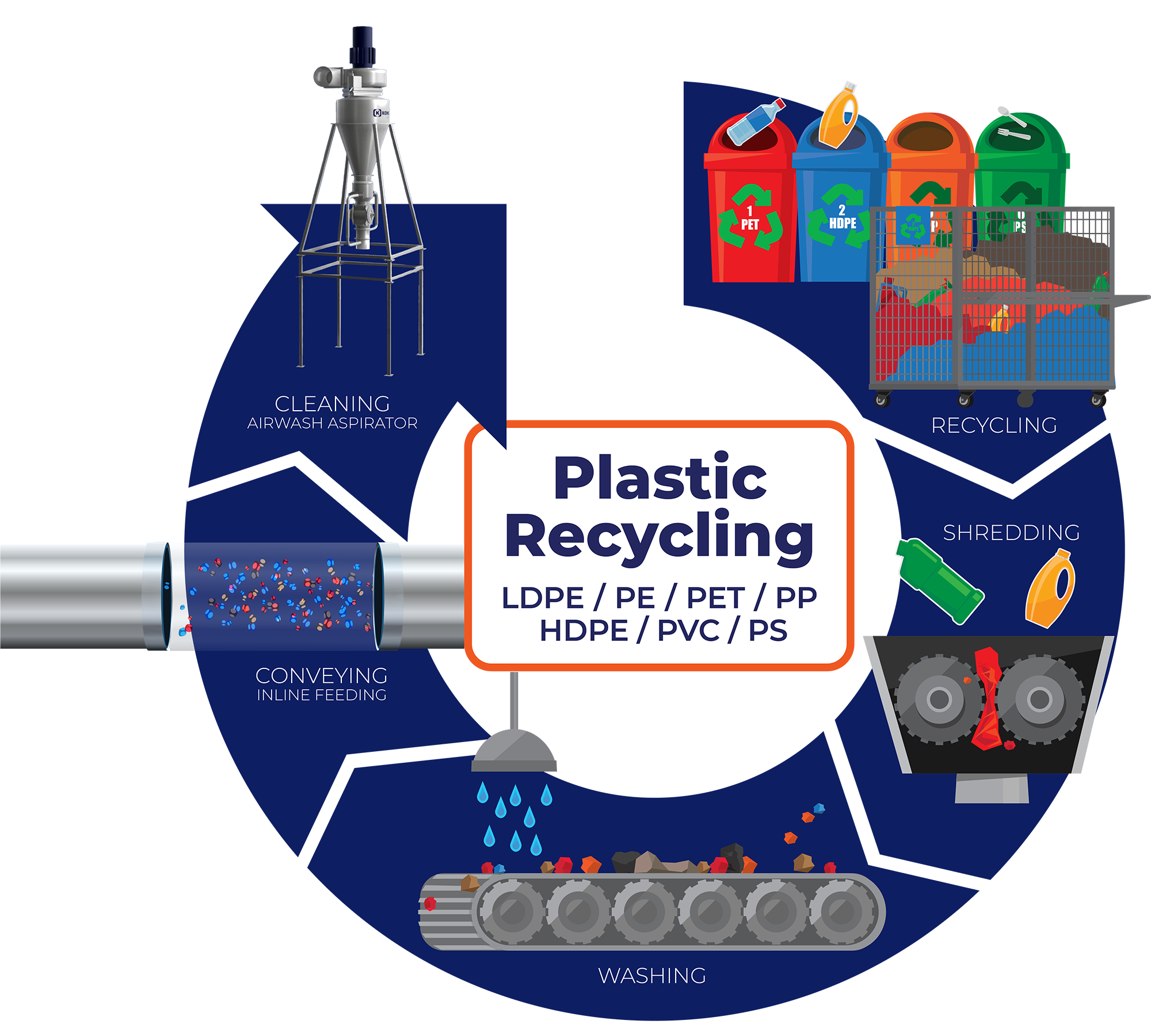

AirWash Separation and Dedusting of Regrind in a Plastics Recycling Plant

The Challenge

A plastics recycling plant overcame the challenge of cleaning regrind material with Kongskilde’s AirWash system. The solution, handling PE and PET dust, achieves max 1000kg/h throughput. Benefits include improved efficiency, higher-quality regranulate, expanded customer base, increased revenue, cleanliness, and reduced maintenance costs and accidents.

In Poland, a plastics recycling plant faced a critical need for regrind cleaning. Kongskilde provided a tailored solution for separating and dedusting light fractions and dust from post-milling materials, ensuring higher quality flakes and regranulates.

Our patented AirWash system enables operators to efficiently remove dust from reprocessed material, ensuring the highest quality flakes and regranulates. Beyond the clear benefit of obtaining clean recycled material, this solution contributes to a healthier work environment by significantly reducing dust, leading to improved employee well-being, accident prevention, and enhanced equipment durability.

The Facts

Material Specifications:

Material: PE dust, PET dust

Bulk density: 450-710 kg/3

Flake size: max. 15x15mm

Regrind percentage: 100%

Throughput: max. 1000kg/h

Volume of dust: max. 10%

System Specifications

Max conveying distance: 10m

Max number of bends: 3

The Solution

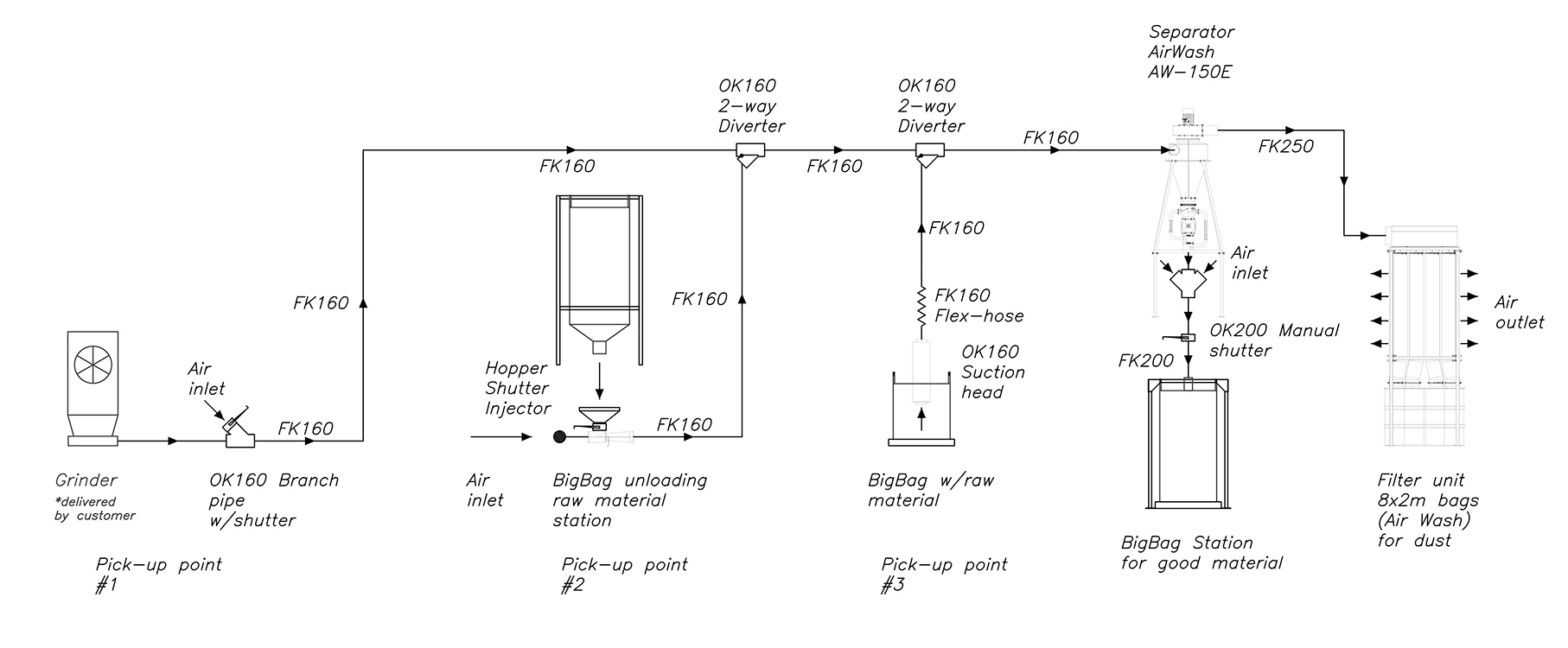

Clean material, processed beneath the AirWash, is stored in a big bag or can be further transported using pneumatic means.

Kongskilde introduced an effective cleaning solution, accommodating regrind from various sources—directly from the mill, mixer discharge, or the suction head discharge from a big bag or octabin.

Pneumatic collection of the ground material is facilitated through the AirWash device, which simultaneously vacuums and cleans the material.

Our solution involves a thorough cleaning process, passing through cyclone and cascade sections, adjusting through zigzag vacuum nozzles, and gravity-discharging via a sealing rotary valve.

Dust and finer fractions are directed through a fan for suction, entering a bag filter before falling into 200-liter drums, serving as convenient dust tanks.

Clean material, processed beneath the AirWash, is stored in a big bag or can be further transported using pneumatic means.

The Advantages and Benefits

By implementing Kongskilde’s automated waste extraction and air filtration system, the factory resolved its core operational challenges, achieving measurable improvements in efficiency, sustainability, and working conditions. The following benefits demonstrate the impact of the solution:

Continuous, Efficient Waste Removal: The pneumatic system enables uninterrupted scrap extraction directly from production lines, minimizing downtime and maintaining consistent workflow.

Cleaner Air and a Healthier Work Environment: Dust and particles are separated from the airflow, which is filtered and recirculated into the hall—improving air quality and ensuring compliance with workplace safety standards.

Reduced Energy Consumption: Blower speed is automatically adjusted based on machine load, optimizing power use and significantly lowering operational energy costs.

With a 75-year legacy of helping companies like yours, we have truly seen it all. We’re creative thinkers, seasoned engineers, and industrial conveyance experts, but most of all, we’re really great problem solvers. Don’t hesitate to ask how we can help.